|

(c) 2012 - 2017 * updated MAR 2020 |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

|

|

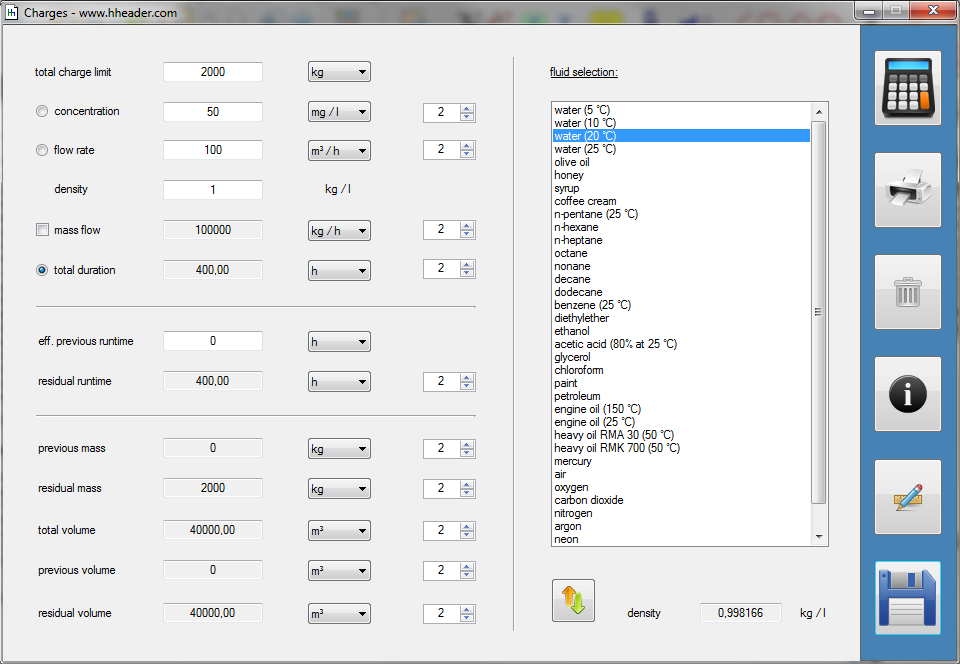

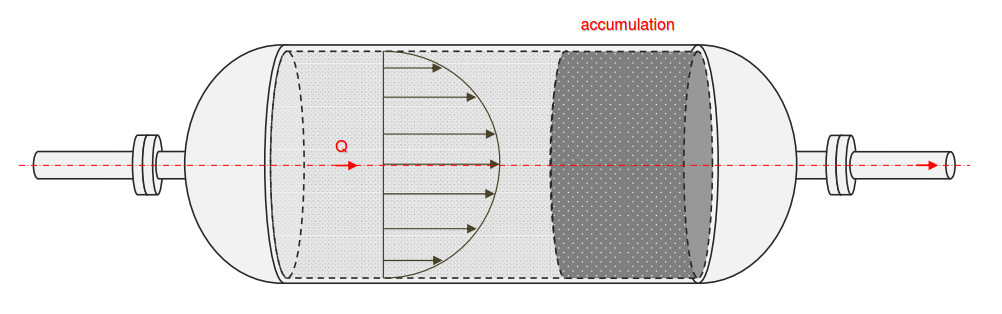

Category 2 - Flow: ChargesEach flow (e.g. air- or water flow) can include a certain content of matter, which is perforce transported with the flow, either as particles or also possibly dissolved or evaporated within the fluid. Sometimes it can be of interest to know the total mass of matter transferred as part of the flow rate by time. Especially if there is a charge limit according to a maximum accumulation for example or for any other reason. The program provides required calculations regarding this subject. A measure for the matter content is its concentration. It defines how many parts of matter are included in how many fluid flow units. Due to this there are three main parameters to be taken into consideration: the flow rate of the fluid, the concentration of matter and the time of operation. |

||||||||||||||||||||

|

|

||||||||||||||||||||

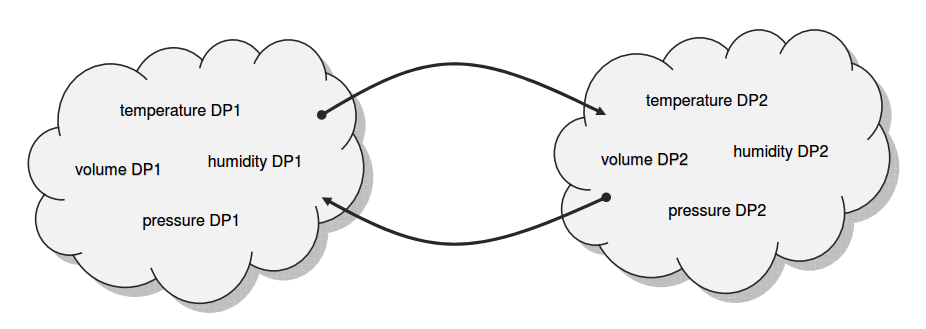

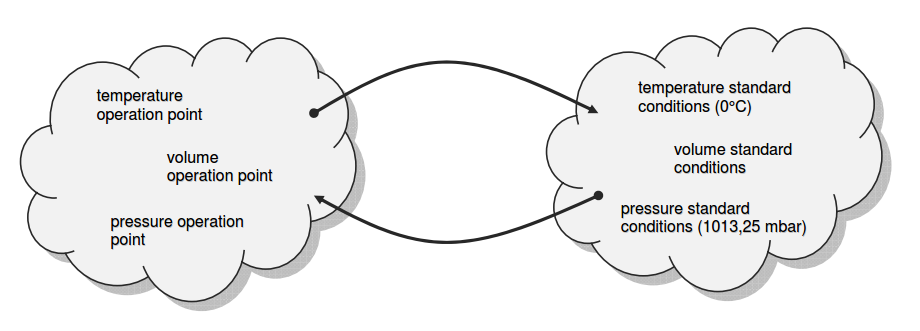

Category 2 - Flow: Operating ConditionsFor any type of gas flows there are different parameters relevant regarding the properties and the behavior under different physical circumstances. While gas is moving from one location to another for example, parameters like pressure, temperature and humidity can change and take effect on the system. Because temperature, pressure and humidity will take influence also on the gas density, it is required to consider gas flow rates under a defined standard condition in order to carry out an adequate evaluation. The standard condition is defined at a temperature of 0°C and a pressure of 1013.25 mbar. Changing the pressure or the temperature will lead to an operating condition and result a different flux. |

||||||||||||||||||||

|

|

||||||||||||||||||||

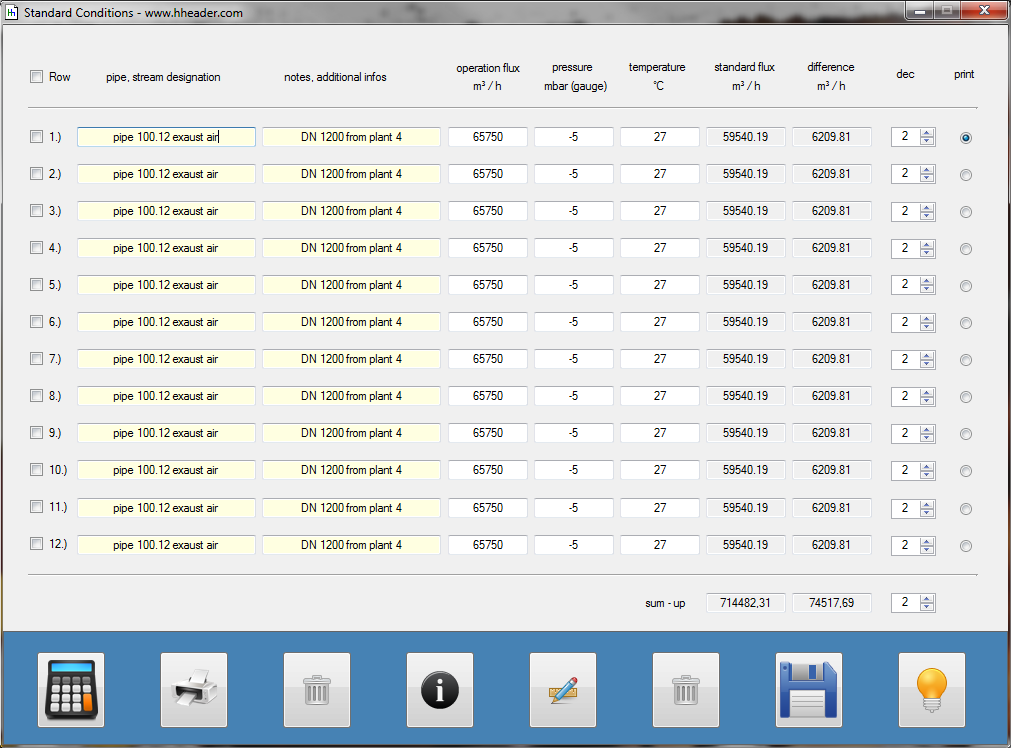

Category 2 - Flow: Standard ConditionsOn site we often find an installed system for the treatment of process- or exhaust air. Therefore the air is usually extracted by suction from different locations of the plant. Generally this is done by a fan. The required flow rates depend on different parameters. The performance of the fan and the pipe installation set-up will amongst other things result corresponding pressures on the suction and pressure side of the fan. Another important parameter is the gas temperature. In order to draw a balance with a sum up and a comparison of all the different flow rates, it is required to consider the flow rate values under equal conditions. These are at least the nominal standard conditions at a temperature of 0 °C and a pressure of 1013.25 mbar. |

||||||||||||||||||||

|

|

||||||||||||||||||||

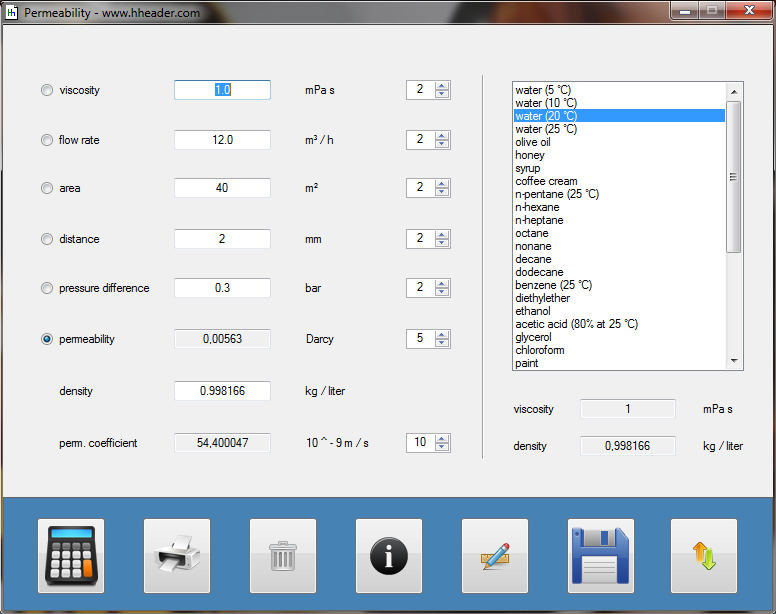

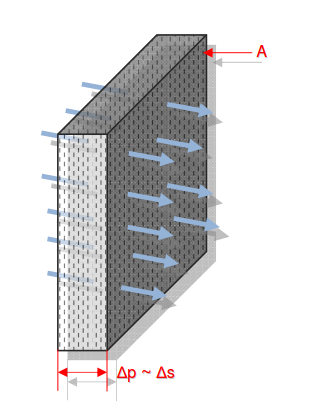

Category 2 - Flow: PermeabilityDepending on the properties and the composition of a material, fluids can pass through it more or less easy or sometimes even not at all. However it can be useful to have a possibility to compare different materials or systems regarding this behavior. A measure for this behavior is the permeability. It can be calculated considering the fluid viscosity, the flow rate, the area of the material and the pressure difference between the inlet and outlet side. The permeability coefficient is also a measure for this. With it also the fluid density is considered. |

||||||||||||||||||||

|

|

||||||||||||||||||||

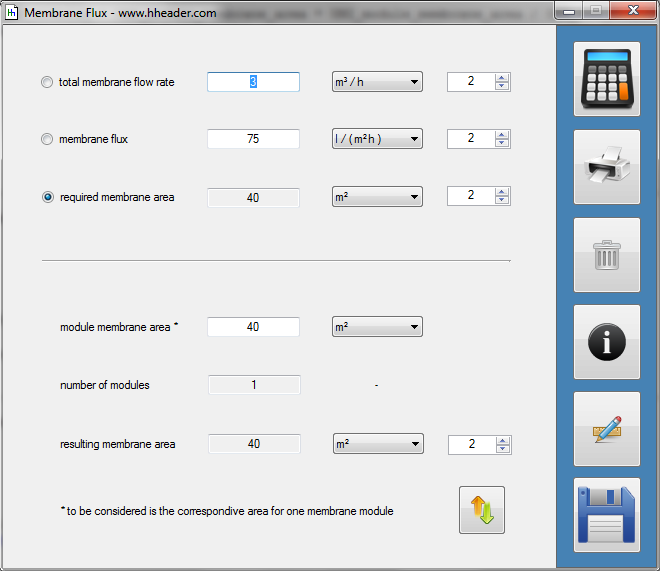

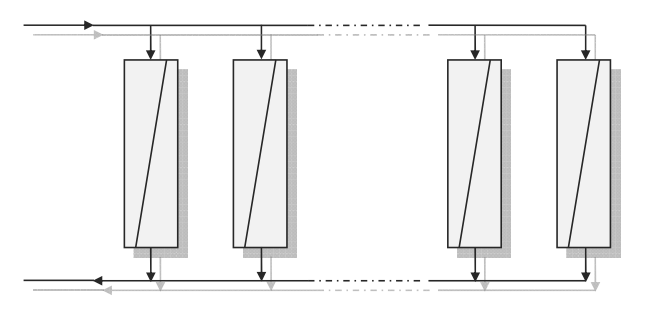

Category 2 - Flow: Membrane FluxAn important parameter for membranes and also for other filters is the maximum load capacity in relation to the area, which is known as membrane flux. This value is usually mentioned in the data sheets of the membranes and it is also depending on the process temperature in many cases. The membrane flux is important for determination of the number of required modules, in case there is a defined flow rate that has to be treated by the membranes. The program provides equations for the flow rate, the membrane flux and the required membrane area. |

||||||||||||||||||||

|

|

||||||||||||||||||||

|

||||||||||||||||||||

|