|

(c) 2012 - 2017 * updated MAR 2020 |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

|

|

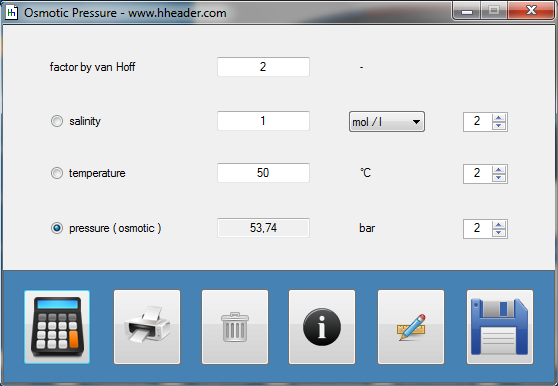

Category 1 - Pressure: Osmotik PressureIt includes the basic calculations for the osmotic pressure due to the ideal gas law. According to the ideal gas law and by taking the factor by van Hoff into consideration the osmotic pressure can be calculated for a given temperature and a given salt concentration (salinity) of the water. Thereby the osmotic pressure increases by increasing temperature. For reverse osmosis plants we often find a decreasing membrane pressure while increasing temperature. This is because the viscosity of the water decreases while increasing temperature. In order to evaluate the pressure circumstances for these systems both, the change of the osmotic pressure and the change of the water viscosity have to be taken into consideration. |

||||

|

|

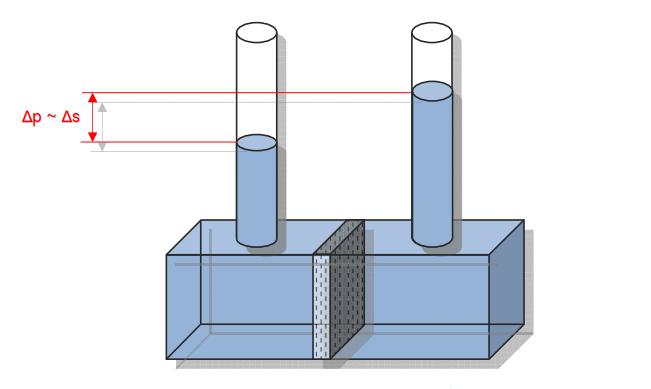

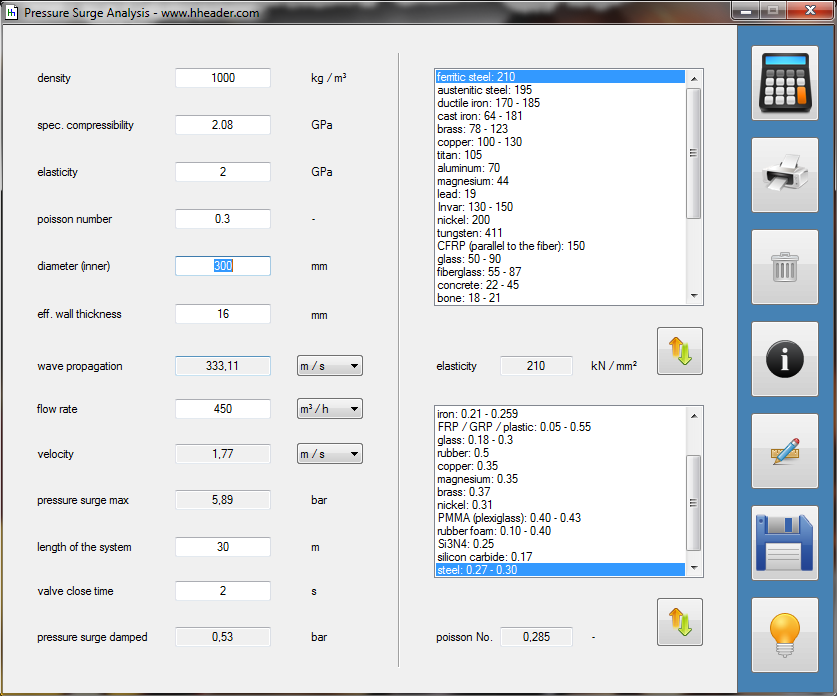

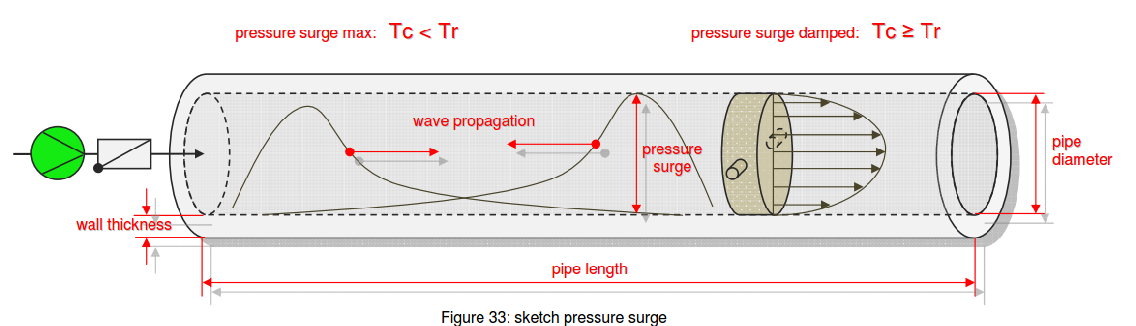

Category 1 - Pressure: Pressure Surge AnalysisIt evaluates the pressure surges to be expected by water hammering. For evaluation of safety conditions and documentation purpose it can be required to do a pressure surge analysis for the pipe installation set-up. Especially if pipe diameter or pipe length are increasing very high pressure surges can appear. In this case it is recommended to evaluate the situation and the probability of high pressure surges. Therefore two different types of pressure surge can be calculated: the maximum pressure surge caused by a suddenly stopped water flow and the damped pressure surge caused by a more or less slowly closing valve. |

|||||||||||||||||

|

|

|||||||||||||||||

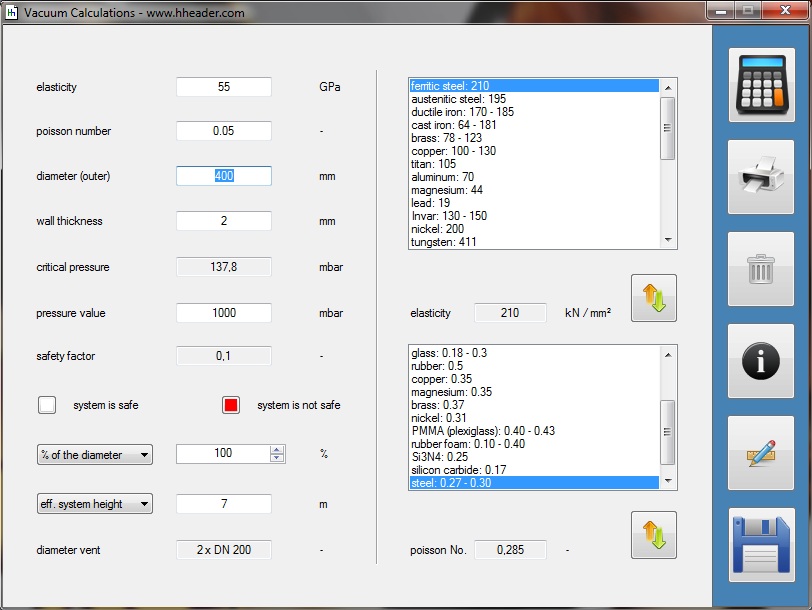

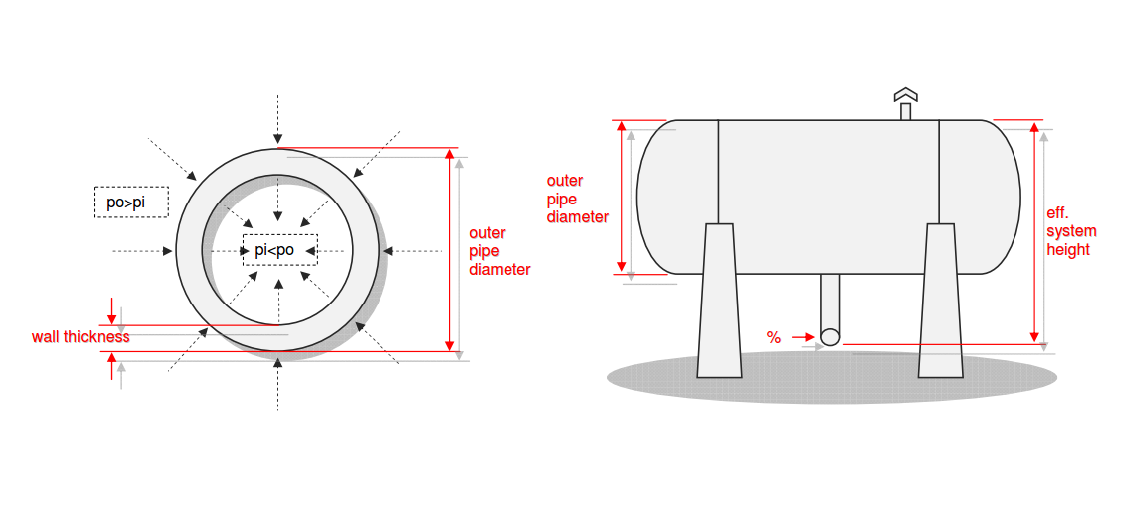

Category 1 - Pressure: Vacuum CalculationsIf the pipe or vessel installation set-up reaches certain heights, there is a danger of damaging compounds by vacuum, especially if an unintended or accidental lowering of the water level takes place. To avoid this there are two possibilities in general: to maintain the required design criteria or to ensure an adequate vent at the top of the installation set-up. By using the program, the design criteria can be checked and a proper vent diameter can be calculated according to the system height. The calculation for the design criteria check-up is based on the following question: what is the value for a pressure outside the compound (e.g. pipe, vessel, etc.) causing the same stress as a corresponding vacuum inside the compound. The result is a critical pressure difference between the outside and the inside of the compound. By this also the actual atmosphere pressure has to be taken into consideration. To evaluate if the system is safe or not a safety factor is calculated by the entered values. According to the latest rules a safety factor of minimum 2.5 is required for a safe system. |

|||||||||||||||||

|

|

|||||||||||||||||

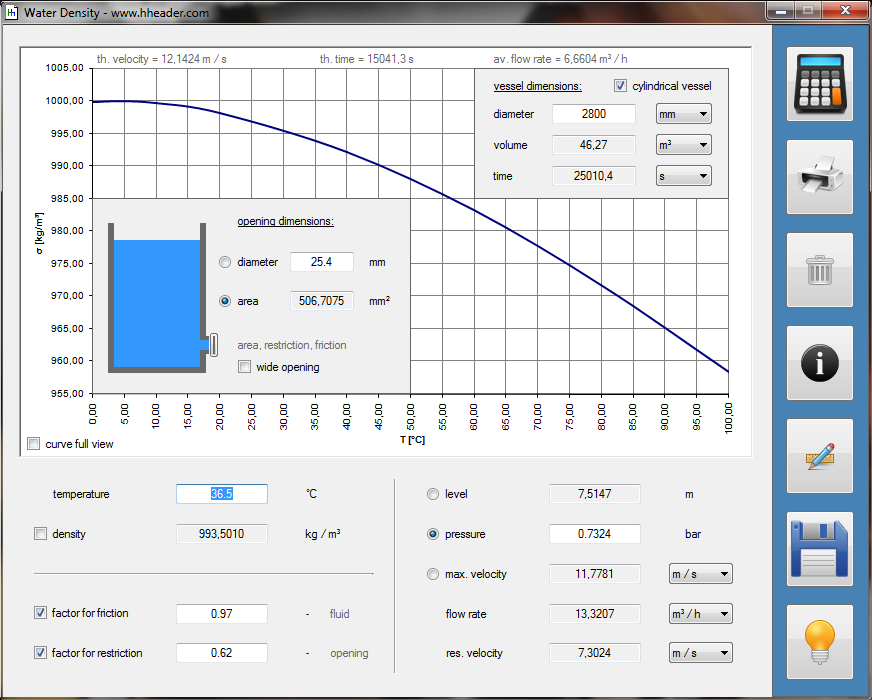

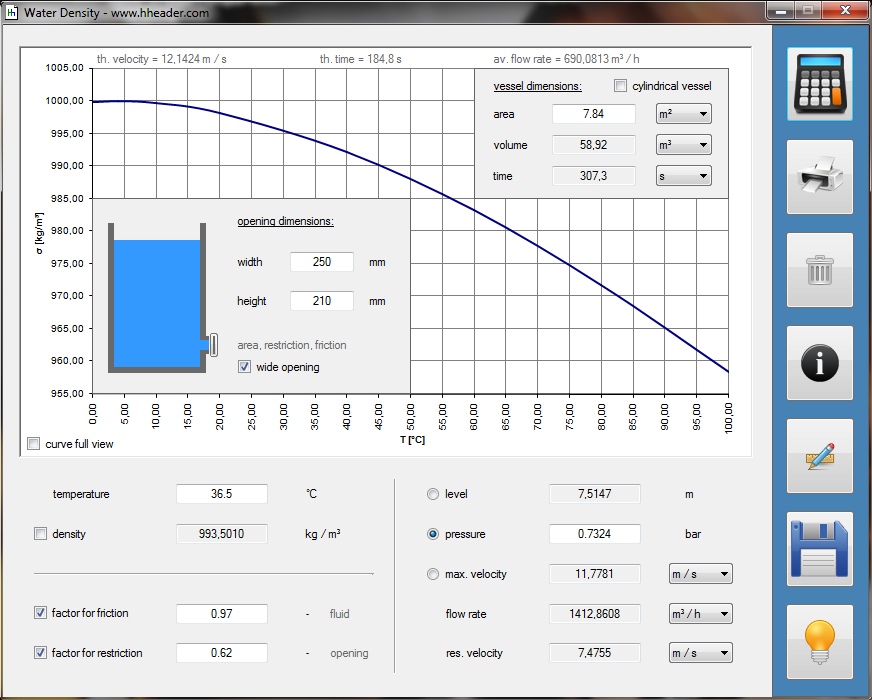

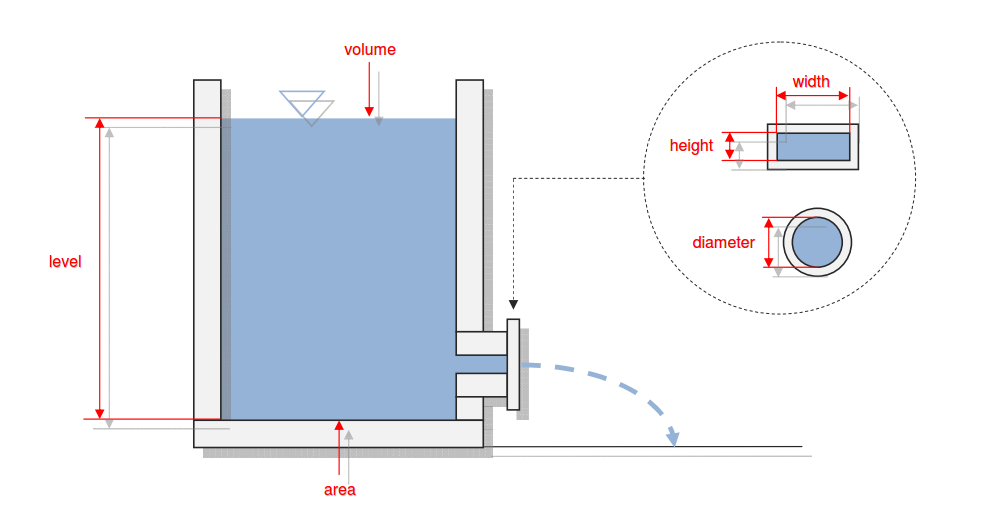

Category 1 - Pressure: Water DensityFor water a default value of 1000 kg/m³ is often assumed. Beside other criteria the temperature of the water takes influence on its density. Water has its highest density value at a temperature of 4°C under atmospheric pressure circumstances. A change of the temperature will cause a change of the density value. This program provides the density as function of the temperature for water. That means I can enter a temperature value and I will get the corresponding density value for this temperature. This is only relevant for water! Thereupon further calculations are possible. |

|||||||||||||||||

|

|

|||||||||||||||||

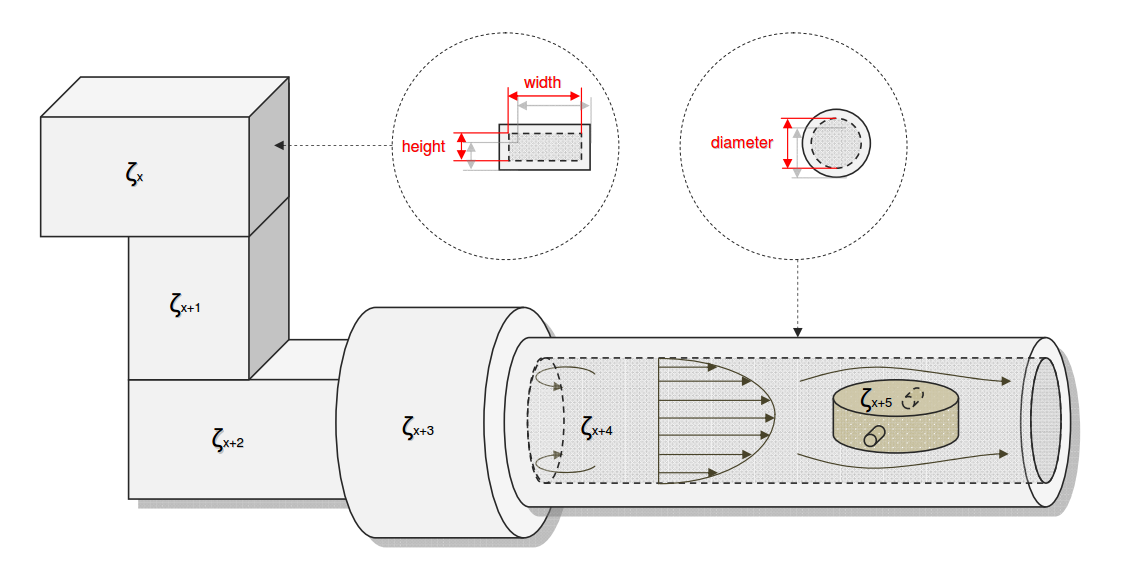

Category 1 - Pressure: Frictional LossesWhenever a fluid, either liquid or gas, is forced moving through a defined pathway, especially if it is a closed system like a tube or a pipe, losses will appear due to friction and resistances caused by the surface properties. According to the dimensions and process values of the system it can be required to evaluate the losses in order to select proper equipment for defined operation purposes. For an adequate evaluation many parameters and properties have to be taken into consideration. These are divided up into different categories: fluid parameters, material parameters, process parameters, dimension parameters and combined resulting parameters. |

|||||||||||||||||

|

|

|||||||||||||||||

|

|||||||||||||||||

|